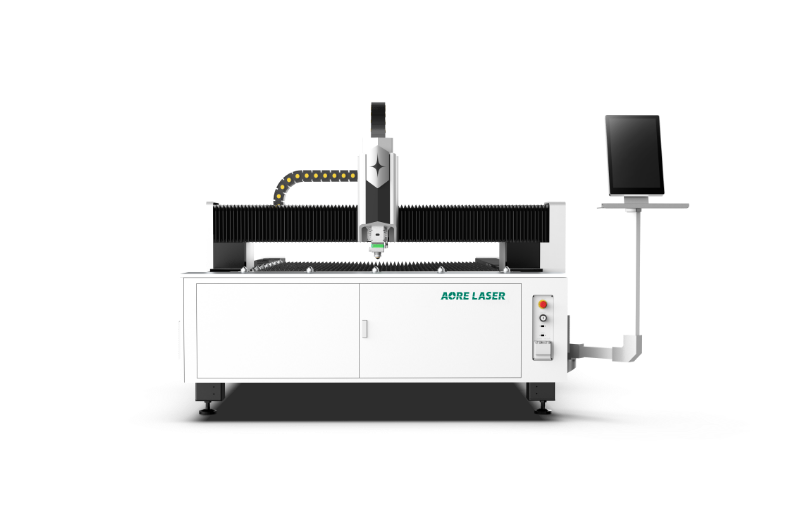

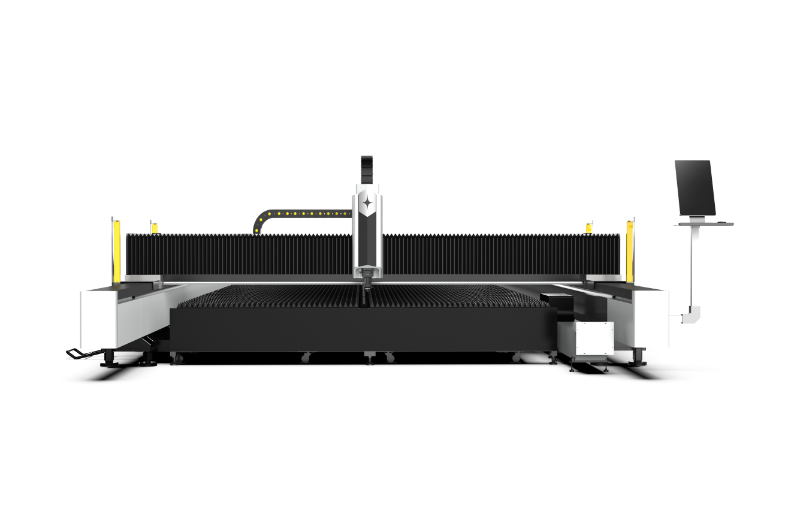

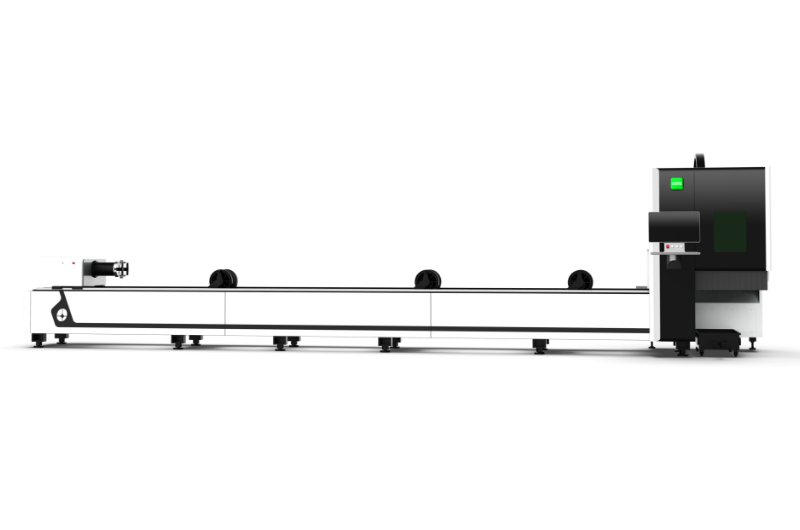

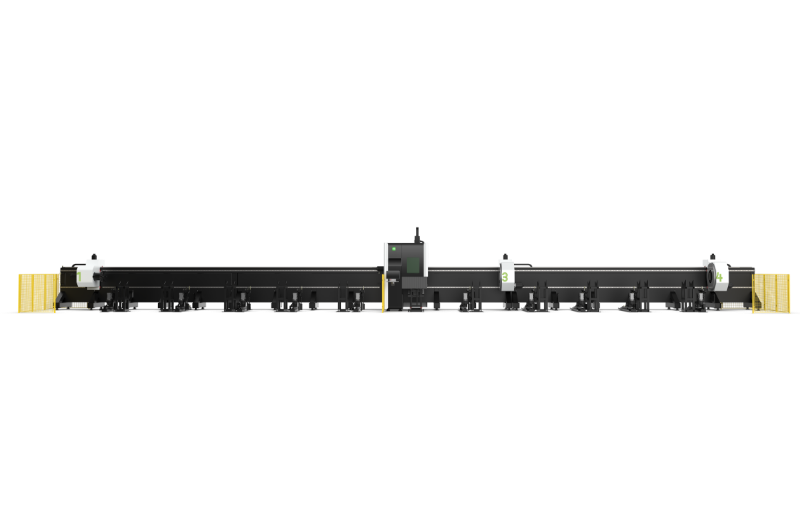

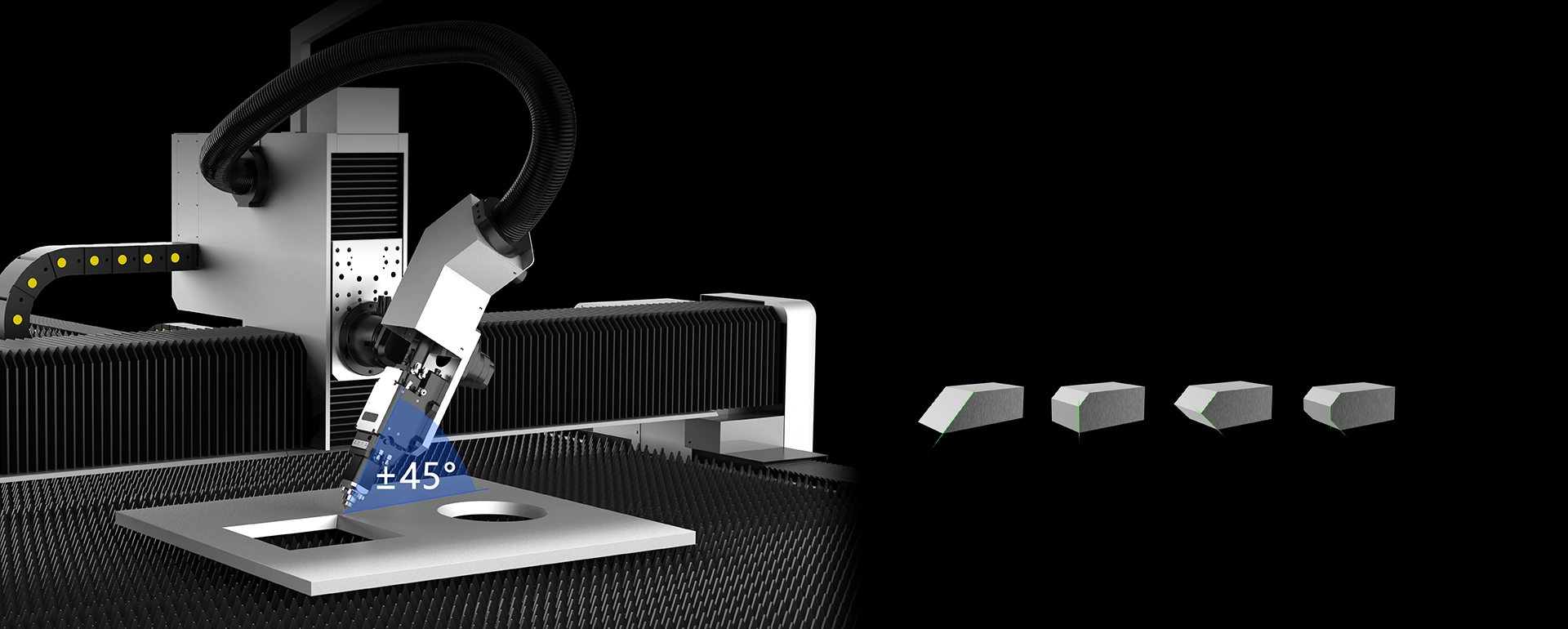

Specializing in laser bevel cutting, our system offers full-scale ±45° bevel cutting with various bevel shapes. This process ensures stability and high efficiency throughout.

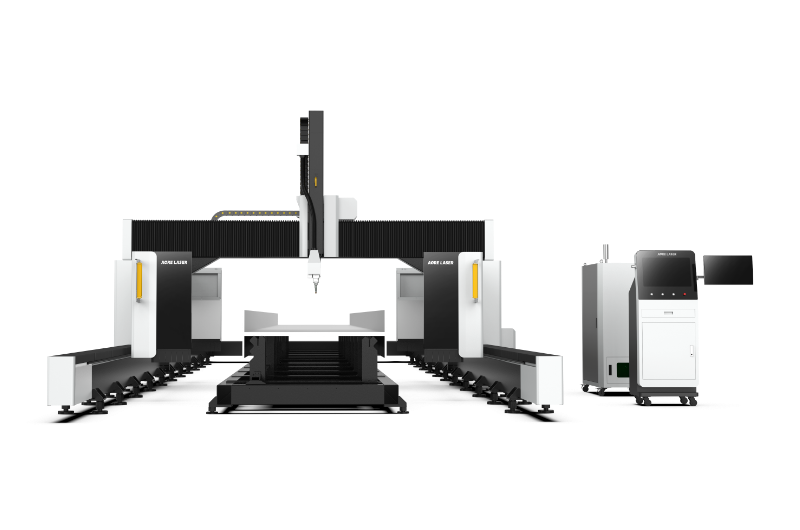

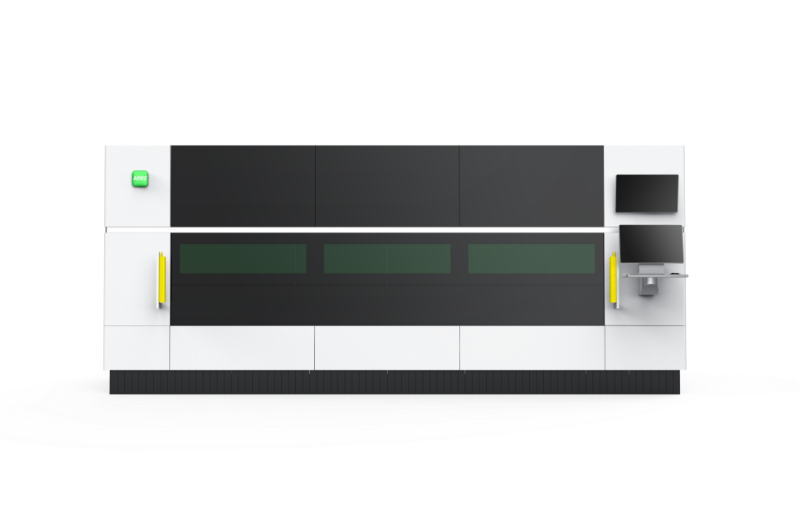

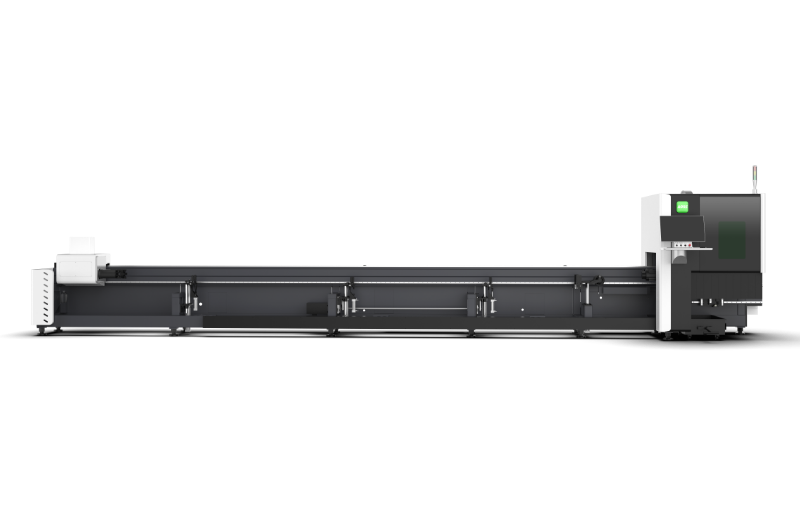

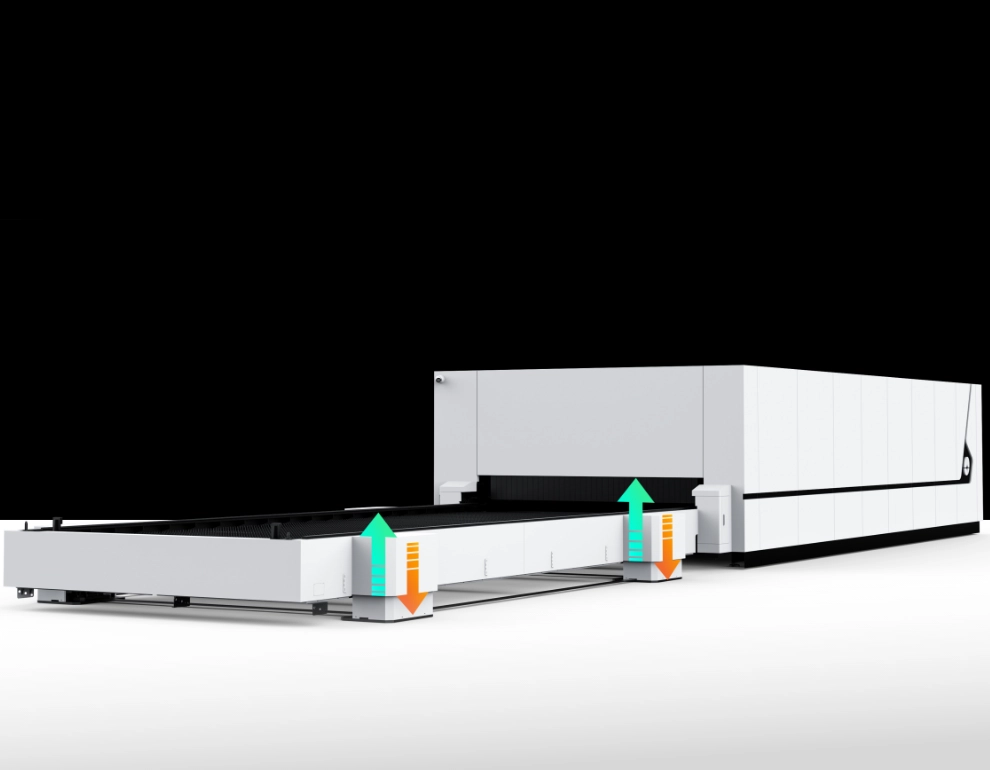

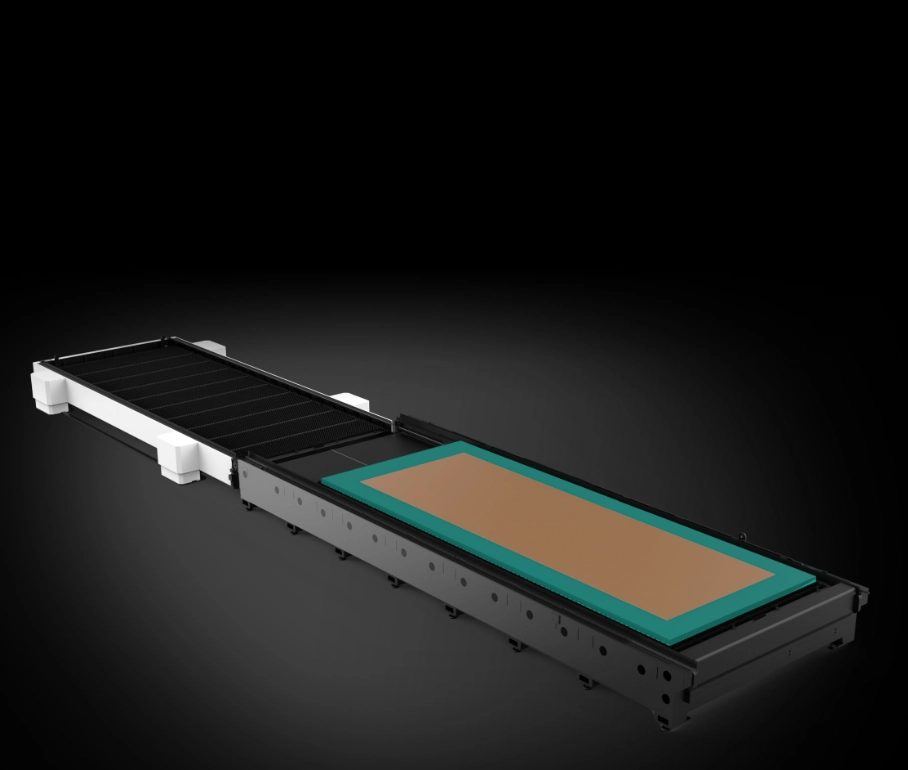

The rear bed features a hydraulic synchronous lift system with single table exchange. This stable and robust structure allows for heavy loads, bringing the table closer to the air outlet for improved air suction. The hydraulic pillar can be adjusted based on the table's load capacity.

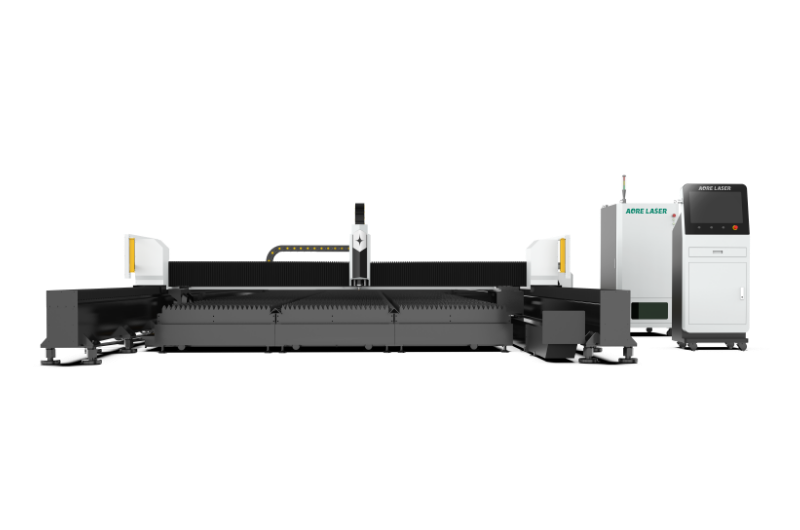

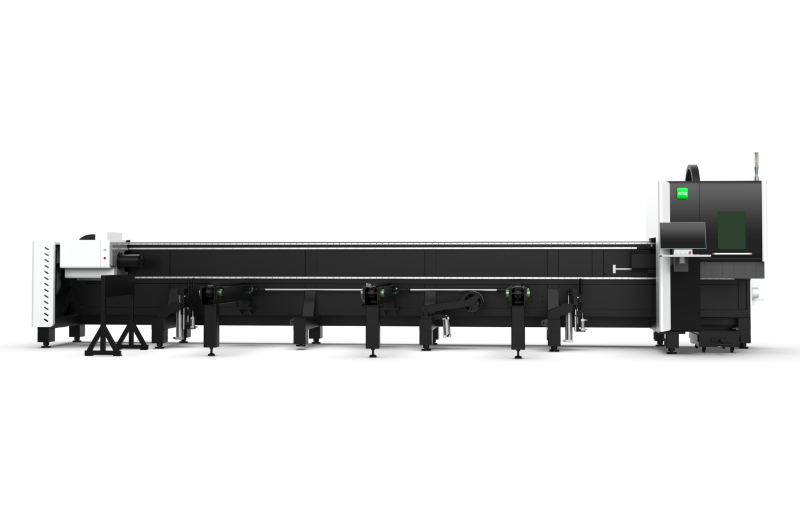

Our technology not only fulfills bevel cutting specifications but also accommodates larger formats for straight cutting, greatly increasing the range of processes available.

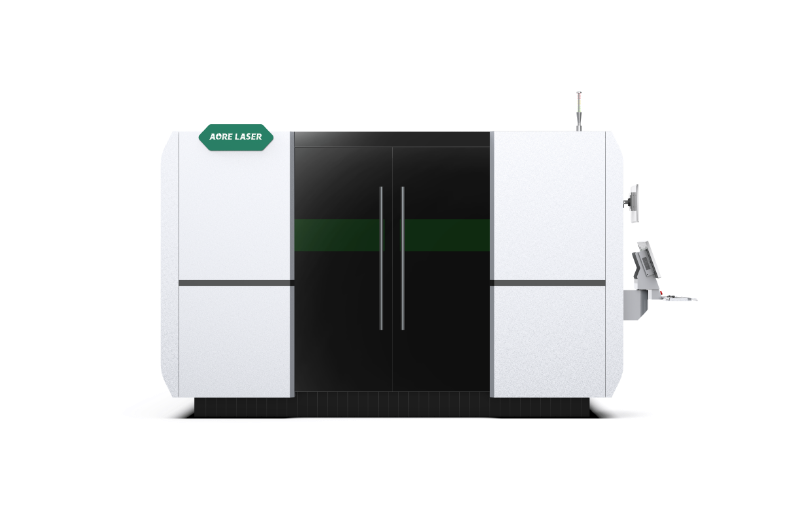

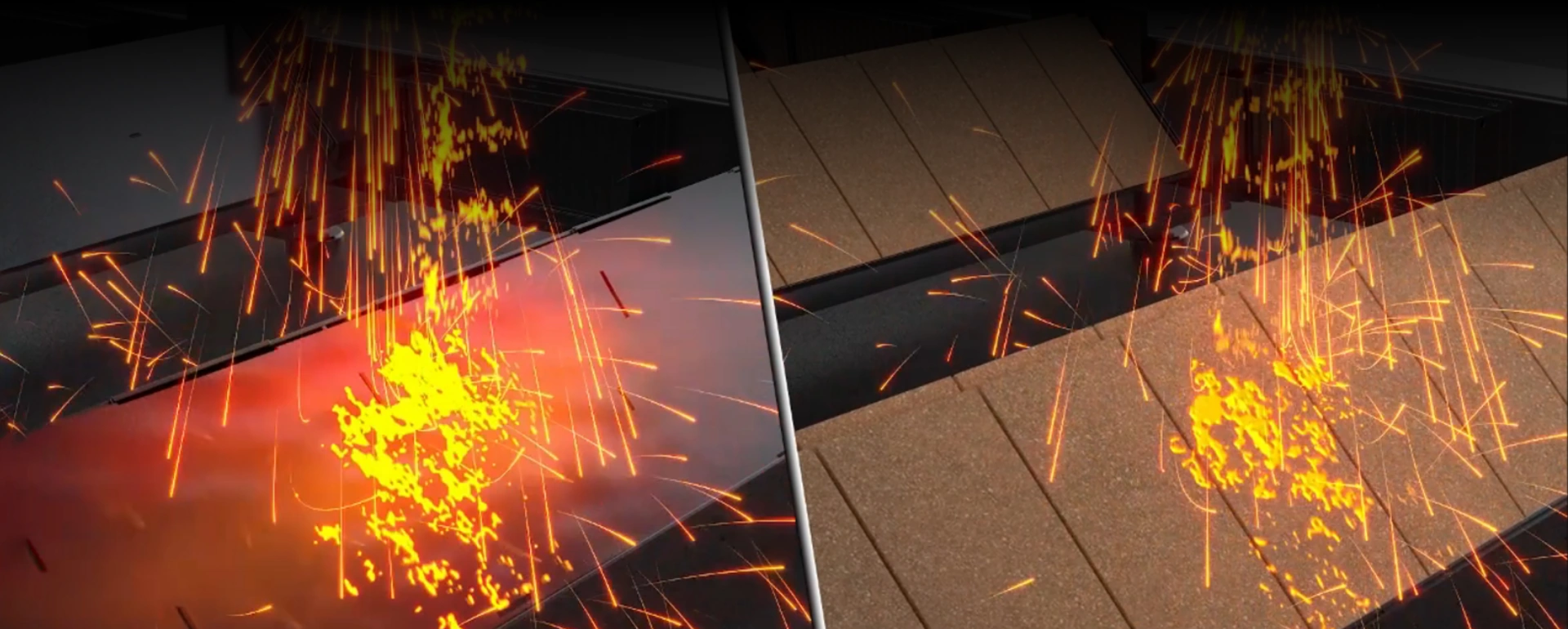

Utilizing cutting-edge fire-resistant and thermal insulation technology, we ensure precise cutting while enhancing the longevity of the equipment.